Quality Specification

Our components are of world class quality. We have a separate quality check team having over 10 years of experience in Aluminium die Castings and this is the reason of our growth in a short duration of time. We are on the verge of getting our company certified. Our company has been working on ISO standards and Quality standards. Many Technologies may come but we use Gauge Quality Check method which is Traditional and Reliable, thus allowing us to enhance the efficiency and quality of the components manufactured here at Puvi Yuthesh Auto Components. All components are created from premium materials to produce the best quality parts in large volume for the best value. Our Quality Products is the main reason why our Customer base is increasing daily.

Strict quality checks are done at every phase of manufacture right from checking the raw material till it is disposed to the customer. Our Experience, passion, enthusiasm and Technical expertise drive us to deliver best quality products on time to our customers.

Production Details and Process Manufacturing:

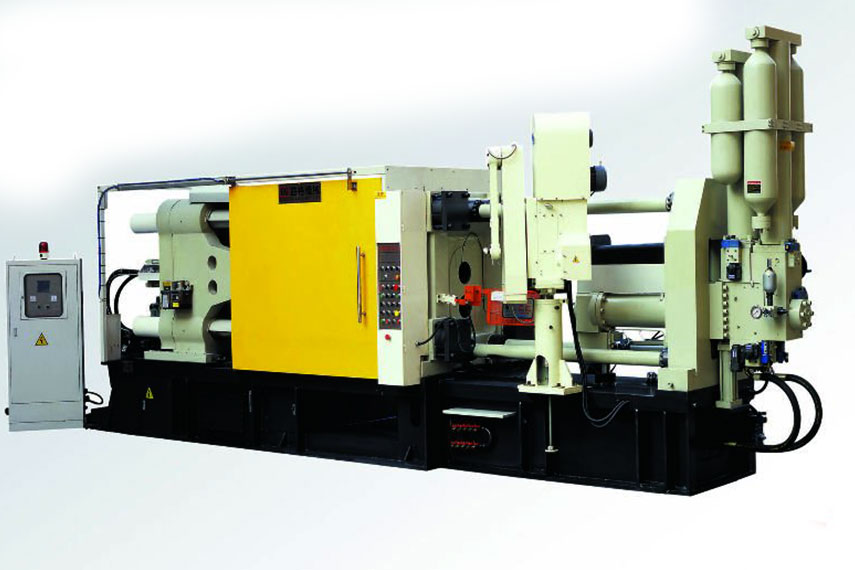

High Melting Point, Aluminium – Silicon alloy is die cast in cold chamber pressure in die casting machine. Metal for a single shot is loaded in to a cylindrical chamber through a pouring aperture a piston then forces the metal into the die, the entire operation being completed in a few seconds so that the iron contamination is virtually eliminated. Using this technique much higher injection pressure in the range of 70 – 140 MP is feasible enabling lower metal to employed greater intricacy achieved. The castings are less prone to entrapped air and a higher standard of soundness ensue from the smaller amount of liquid and solidification shrinkage occurring within the die.