Aluminum

The metallic element aluminum is the third most plentiful element in the earth's crust, comprising 8% of the planet's soil and rocks (oxygen and silicon make up 47% and 28%, respectively). In nature, aluminum is found only in chemical compounds with other elements such as sulphur, silicon, and oxygen. Pure, metallic aluminum can be economically produced only from aluminum oxide ore.

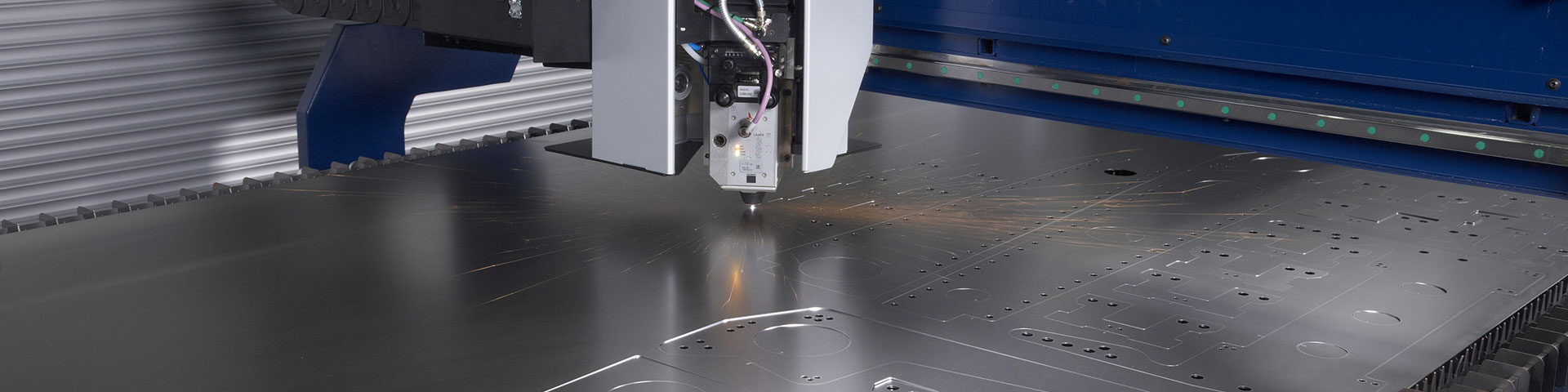

Metallic aluminum has many properties that make it useful in a wide range of applications. It is lightweight, strong, nonmagnetic, and nontoxic. It conducts heat and electricity and reflects heat and light. It is strong but easily workable, and it retains its strength under extreme cold without becoming brittle. The surface of aluminum quickly oxidizes to form an invisible barrier to corrosion. Furthermore, aluminum can easily and economically be recycled into new products.

Raw Materials

Aluminum compounds occur in all types of clay, but the ore that is most useful for producing pure aluminum is bauxite. Bauxite consists of 45-60% aluminum oxide, along with various impurities such as sand, iron, and other metals. Although some bauxite deposits are hard rock, most consist of relatively soft dirt that is easily dug from open-pit mines. Australia produces more than one-third of the world's supply of bauxite. It takes about 4 lb (2 kg) of bauxite to produce 1 lb (0.5 kg) of aluminum metal.

Caustic soda (sodium hydroxide) is used to dissolve the aluminum compounds found in the bauxite, separating them from the impurities. Depending on the composition of the bauxite ore, relatively small amounts of other chemicals may be used in the extraction of aluminum.

Some Facts

Since the early 1990s, the aluminum industry has decreased greenhouse gas emissions from primary production by 37 percent and from secondary production by more than 50 percent.

Secondary production (aluminum produced from recycled material) saves more than 90 percent of the energy required to produce primary aluminum. Secondary and primary aluminum are chemically indistinguishable from one another.

The metal is 100 percent recyclable without loss of the metal’s properties. Recycling is also widespread. According to a study by Delft University of Technology in 2012 in Seattle, WA, more than 90 percent of aluminum in buildings is recycled.

The use of aluminum to make industrial products inherently brings sustainable results. As an example, structures built with aluminum exteriors naturally reflect light and remain cooler.

Today’s consumers are demanding energy efficiency, and aluminum can play a key role in driving this change. In August 2012, the U.S. government set higher Corporate Average Fuel Economy (CAFE) standards, mandating an average fuel economy of 54.5 miles per gallon for the 2025 model year. Because the use of aluminum provides significant weight reductions for automakers, many car companies are now moving to aluminum to achieve these goals. In fact, in 2009, aluminum’s use in road vehicles offset more than 90 percent of all greenhouse gas emissions associated with aluminum production in North America.